YiRui Metalは、高品質のマグネシウム合金AZ91Dシリーズを6KGと12KGの重量で供給します。 その他の仕様は事前にカスタマイズする必要があります。

AZ91Dマグネシウム合金は、幅広い用途で一般的に使用されている高強度の軽量素材です。 マグネシウム、アルミニウム、亜鉛で構成されており、優れた耐食性、優れた機械加工性、高い熱伝導率で知られています。

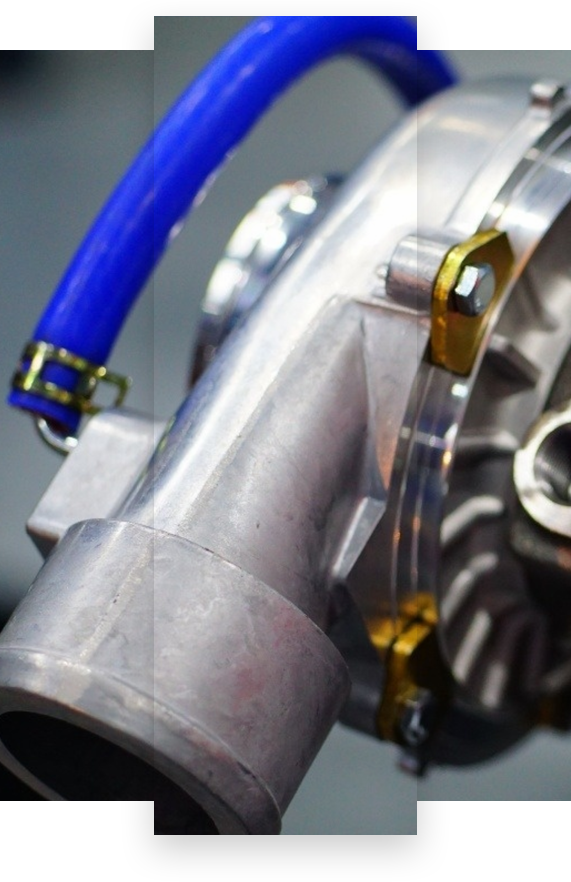

AZ91Dマグネシウムは、ホイール、ステアリングホイール、ギアボックスケーシングなどの部品の製造に使用される自動車業界で特に人気があります。 また、家電、航空宇宙部品、医療機器の製造にも使用されています。

| Composition(%) | |||||||||||

| Brand | Standard | Al | Zn | Mn | Fe (max) | Be (ppm) | Si (max) | Cu (max) | Ni (max) | Ca | Na |

| AZ91D | ASTM | 8.5-9.5 | 0.45-0.90 | 0.17-0.4 | 0.004 | 5-15 | 0.05 | 0.026 | 0.001 | ||

| VW030 | ASTM | 7.0-8.5 | 0.30-1.0 | 0.10-0.30 | 0.004 | 5-15 | 0.2 | 0.08 | 0.01 | ||

| AZX211 | ASTM | 1.7-2.1 | 0.8-1.0 | 0.2-0.4 | 0.005 | 8-13 | 0.04 | 0.003 | 0.002 | 0.55-0.75 | 0.002 |

| AM50A | ASTM | 4.5-5.3 | 0.15max | 0.28-0.5 | 0.004 | 6-15 | 0.05 | 0.008 | 0.001 | ||

| AM60B | ASTM | 5.6-6.4 | 0.2max | 0.26-0.5 | 0.004 | 5-15 | 0.05 | 0.008 | 0.001 | ||

AZ91D is a magnesium alloy that is commonly used in various applications due to its desirable mechanical properties. Here are some of its mechanical properties:

Tensile Strength: magnesium alloy AZ91D has a tensile strength of 230 MPa (MegaPascals) in the as-cast condition, and it can be improved up to 270 MPa through appropriate heat treatment.

Yield Strength: The yield strength of magnesium alloy AZ91D is 140 MPa in the as-cast condition and can be improved up to 200 MPa with heat treatment.

Elastic Modulus: The elastic modulus of magnesium AZ91D is around 45 GPa (GigaPascals), which is lower than that of aluminum alloys and steel.

Ductility: AZ91D has good ductility, which means it can be easily formed into complex shapes. Its elongation at break is typically around 3-4%.

Fatigue Strength: The fatigue strength of magnesium alloy AZ91D is moderate compared to other engineering materials, and it decreases with increasing cyclic stress.

Overall, AZ91D is a lightweight material with good strength and ductility, making it an attractive choice for applications where weight reduction is important. However, it should be noted that magnesium alloys are prone to corrosion, so appropriate measures need to be taken to prevent corrosion in service.

Density: The density of magnesium AZ91D is around 1.78 g/cm³, which is about one-third the density of steel and two-thirds the density of aluminum.

Melting Point: The melting point of magnesium alloy AZ91D is approximately 570°C (1060°F).

Thermal Conductivity: The thermal conductivity of magnesium alloy AZ91D is lower than that of aluminum alloys and steel, but higher than most plastics. It is around 75 W/mK (Watts per meter Kelvin) at room temperature.

Coefficient of Thermal Expansion: The coefficient of thermal expansion of magnesium alloy AZ91D is relatively high, around 26 x 10^-6/K (per Kelvin) in the temperature range of 20-100°C.

Electrical Conductivity: The electrical conductivity of magnesium AZ91D is relatively low, around 15% that of copper.

Magnetic Properties: magnesium AZ91D is not magnetic, which makes it suitable for applications where magnetic interference needs to be avoided.

AZ91D magnesium alloy is a commonly used magnesium alloy in various industrial applications. It is a cast alloy, which means it is formed by pouring molten metal into a mold and allowing it to solidify.

Magnesium in automotive industry: AZ91D magnesium alloy is commonly used in the automotive industry for components such as engine blocks, transmission cases, and wheels. Its lightweight properties make it an attractive material for reducing the weight of vehicles, which can improve fuel efficiency and reduce emissions.

Magnesium alloy in aircraft: The alloy is also used in the aerospace industry for applications such as aircraft engine components, and in the electronics industry for housings and frames of devices like laptops and smartphones.

Other applications of AZ91D magnesium alloy include sporting goods such as golf club heads and bicycle frames, as well as medical implants and orthopedic devices due to its biocompatibility and strength-to-weight ratio.

Reference

https://pubmed.ncbi.nlm.nih.gov/34771971/

https://www.sciencedirect.com/science/article/pii/S2213956722001530

マグネシウム合金AZ91Dは主に圧力ダイによって鋳造され、純粋なマグネシウムと比較して高い比強度と大幅に改善された耐食性を特徴としています。 この贩売のためのマグネシウムの合金主に電気製品のシェル、小型の薄いまたは特殊な形状のサポートなどに使用されます。

AZ91D合金は強度と重量の比率が高いため、重量を最小限に抑えながら強度と耐久性を必要とする用途に理想的な材料となっています。 密度は1.78g/cm ³ で、アルミニウムの約3分の2、鋼の4分の1です。

AZ91Dの主な利点の1つは、他のほとんどのマグネシウム合金よりも優れた優れた耐食性です。 これにより、海洋や腐食性の産業環境などの過酷な環境での使用に適した材料になります。さらに、AZ91Dマグネシウム合金は簡単に機械加工できるため、公差の厳しい複雑な形状や部品を作成できます。 また、さまざまな形状やサイズにキャストすることができ、さまざまな用途に用途の広い素材になります。

全体的に、AZ91Dマグネシウム合金は、強度、耐久性、軽量のユニークな組み合わせを提供する高性能素材です。 さまざまな業界で広く使用されており、高い強度と耐食性が必要なアプリケーションに最適です。